Call us

Call us

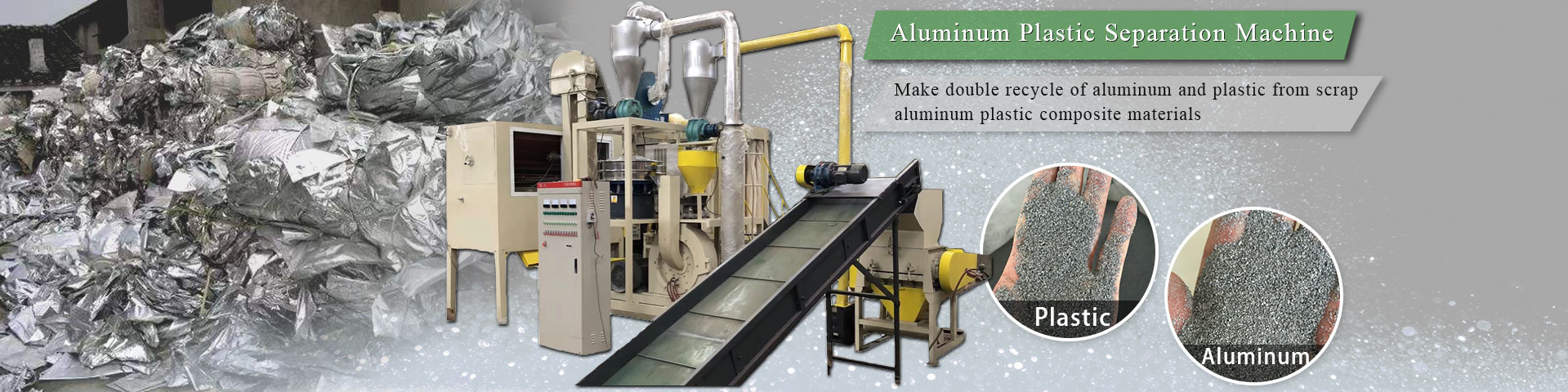

Plastic and Aluminum Recycling Machine For Sale

Plastic and aluminum recycling machine designed by Henan Doing Mechanical Equipment Co., Ltd is specially for separating plastic and aluminum of aluminum plastic composite materials through new type and green technology. The process include crushing, grinding, water cooling, rotarty vibrating screen and electrostatic separation, a dry type physical separation way, no water, no chemical, no fire, totally pollution-free. The separation rate of our plastic and aluminum recycling machine could reach to 99%, and the separated plastic and aluminum could be directly recycled to be sold in the market or made into new products. Compared to low value scrap and waste aluminum plastic composite materials, the recycled pure plastic and aluminum would bring high benefit. It makes the plastic and aluminum recycling machine a good business to start with.

- WhatsApp:

+86-150-3713-8562

- Tel:

+86-150-3713-8562

- Phone:

+86-371-5677-1821

- Email:

sales@doinggroup.com

Input Material - Plastic and Aluminum Recycling Machine

What's the aluminum content in different materials?

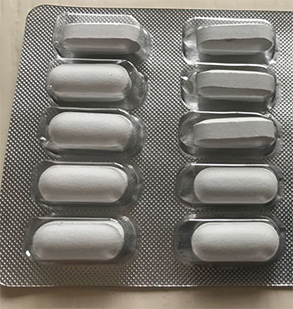

The plastic and aluminum recycling machine applys to process many kinds of aluminum plastic composite materials, such as aluminum-plastic medical blister packs, aluminum plastic composite panels, aluminum-plastic tubes, pipelines, and aluminum-plastic packages, films, etc. Below are 4 types typical aluminum-plastic composite mateials, in which shows the aluminum content separately.

-

12-70%

Medical blister packs

-

10-35%

Aluminum-plastic panel

-

20-25%

Aluminum-plastic pipe

-

16-35%

Aluminum-plastic flim

Running Video - Plastic and Aluminum Recycling Machine

Working process of plastic and aluminum recycling machine

From this video, you could check how plastic and aluminum are separated from scrap aluminum plastic composite medical bliter packs through a crushing, grinding and separation process. This machine in the video is also called as medical blister pack recycling machine, but also used for the other aluminum plastic composite materials.

Specification - Plastic and Aluminum Recycling Machine

| General Model | Capacity (kg/h) | Power(kw) | Dimension (mm) | Weight (kg) | Separation Rate |

| DY-300 | 200-300 | 70 | 7500*6000*4200 | 6500 | ≥99% |

| DY-600 | 500-600 | 115 | 9500*7500*4200 | 7800 | |

| DY-800 | 700-800 | 215 | 11500*8000*4200 | 12800 |

Advantages - Plastic and Aluminum Recycling Machine

-

Fully automatic PLC control

The whole process of our plastic and aluminum recycling machine is under PLC control, fully automatic, easy to operate.

-

High voltage electrostatic separation

The aluminum plastic separation process adopts electrostatic separation technology, dry type physical separation method, no fire, no water, no chemical, totally clean and pollution-free.

-

Water cooling for high separation rate

The crushing and grinding process working with water cooling system, which avoid high temperature generated to make plastic melted and stick on aluminum, ensure the high separation rate.

-

High efficiency pulse dust collector

The plastic and aluminum recycling machine is equipped with pulse dust collector, which could make sure a clean working environment without dust fly around.