Call us

Call us

Benefits of aluminum plastic panel separator machine

Benefits of aluminum plastic panel separator machine is strong practicability (high profitable by recycling), high efficiency, low noise, and separation of the final product purity is very high, can reach more than 99%.

With the speeding up of economic development, the aluminum composite materials are widely used in the production and living, increase of usage, annual produce metal and nonmetallic compounds up to hundreds of millions of tons of garbage, including sheet metal, aluminum tubes, aluminum-plastic plate, toothpaste, aluminum-plastic packaging materials, this waste, without effective treatment, will take up a large land area, and the material of metal and polymer is contained in it is difficult to natural degradation, anywhere will have a significant impact on atmosphere, water, soil.

Aluminum plastic composite materials

Aluminum plastic composite materials

We DOING group developed the new environment-friendly aluminum-plastic separator can successfully separate aluminum-plastic composite material into aluminum and plastic through completely dry physical separation technology, without causing secondary pollution to the environment.

Aluminum plastic panel separator machine

Aluminum plastic panel separator machine

The first benefits of aluminum plastic panel separator machine is energy saving and environmental protection, no need to separate aluminum and plastic by washing, and no need to burn fuel.

The second benefits of aluminum plastic panel separator machine is sealed processing, safe and hygienic. In the separation process of aluminum-plastic products, the separation separator is completed in a completely sealed environment, and the separated dust is automatically collected into a dust bag to keep the environment clean.

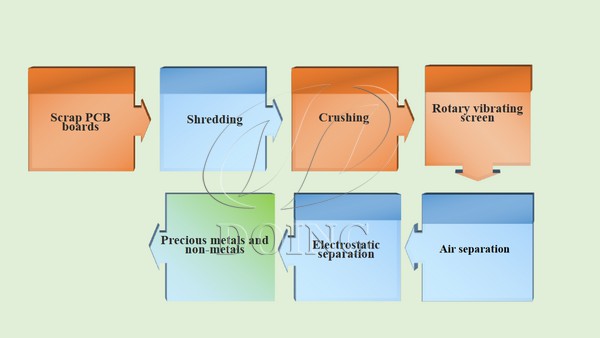

Process of aluminum plastic panel separator machine

Process of aluminum plastic panel separator machine

The third benefits of aluminum plastic panel separator machine is high separation rate. The aluminum-plastic separator developed by our DOING company can completely separate aluminum and plastic through physical crushing, grinding, rotating vibrating screen, electrostatic separation and other processes, and the separation rate reaches more than 99%. Recycled aluminum not only can be used to smelt aluminum ingots, but also silver powder factory, fireworks factory, aluminum factory, the quality raw materials. According to market research, it costs up to $2,200 a ton. In addition, the recycled plastic can be compressed, pipe packaging and water pipeline. Market potential is huge, extremely high return.

Considering the above three benefits of aluminum plastic panel separator machine then don’t hesitate to recycle your aluminum plastic waste to make money! Welcome contact with us for further information about aluminum plastic panel separator machine.

Contact Us

- WhatsApp:

+86-150-3713-8562

- Email:

sales@doinggroup.com

- Tel:

+86-150-3713-8562

- Phone:

+86-371-5677-1821

News

-

400-500kg/h aluminum plastic recycling machine was shipped to Xinxiang, China

-

New order -- the customer from Taiwan, China ordered an aluminum plastic recycling machine

-

Customer from UAE visited Henan DOING for inspecting aluminum plastic recycling machine

-

-

A 400-500kg/h aluminum plastic recycling machine was ordered by a Chinese customer from Henan DOING