Call us

Call us

How to separate aluminum from plastic?

There are a lot of waste aluminum-plastic composite materials in the market, so the separation of aluminum-plastic has become a hot spot of investment. However, the traditional separation method of chemical method has been eliminated due to its high cost, cumbersome process, pollution to the environment and harm to human beings, and now it mainly uses he method of physical separation to separate aluminum from plastic.

With the rapid development of modern industrial technology, the technology and products with each passing day, more and more aluminum products has been widely used in people's life in various fields, such as food factory, cigarette factories, pharmaceutical factory, modern decoration materials, chemical industry and so on product packaging), has provided people with convenient, at the same time also brought a lot of disadvantage. Its bits and pieces and castoff (waste soft packaging bag, capsule board, tooth plaster, etc.) not only all over the place, and into every corner of people's lives. So much, not only pollute the environment and caused a great waste of resources.

Aluminum-plastic composites

Aluminum-plastic composites

The aluminum in these aluminum-plastic composites is extremely pure and expensive, and it would be very economical to separate the aluminum from the plastic. It is based on this situation that DOING company produces aluminum plastic separation equipment. Aluminum plastic separation equipment using a completely dry physical separation method separated aluminum from the plastic, to achieve the recovery and reuse of resources.

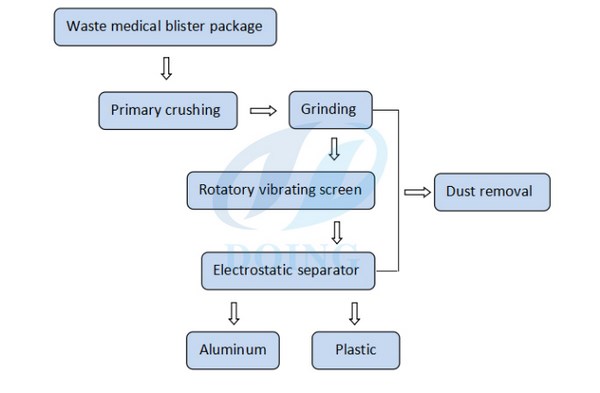

The process of separating aluminum from plastics by the aluminum plastic separation equipment is as follows:

1.Crushing

put the aluminum and plastic products into a crusher to break them into smaller particles.

2.Grinding

broken aluminum particles for grinding, are processed into powder.

3.Spin vibration sieve

The powder mixture of aluminum and plastic was put into the spin vibration sieve for screening, and the larger particles were screened out for grinding again;

4.Electrostatic separation

the small particles after the treatment of rotary sieve for electrostatic separation, so as to separate aluminum and plastic powder.

The process of separating aluminum from plastic

The process of separating aluminum from plastic

Aluminum plastic separation equipment equipped with dust removal device, will not cause secondary environmental pollution, and low cost, simple operation. It is the best choice to use the separation equipment to separate the aluminum from the plastic.

Contact Us

- WhatsApp:

+86-150-3713-8562

- Email:

sales@doinggroup.com

- Tel:

+86-150-3713-8562

- Phone:

+86-371-5677-1821

News

-

400-500kg/h aluminum plastic recycling machine was shipped to Xinxiang, China

-

New order -- the customer from Taiwan, China ordered an aluminum plastic recycling machine

-

Customer from UAE visited Henan DOING for inspecting aluminum plastic recycling machine

-

-

A 400-500kg/h aluminum plastic recycling machine was ordered by a Chinese customer from Henan DOING